836 Landfill Compactor

Landfill Compactors

Details

Gross Power (SAE J1995:2014)

562 HP

Net Power (SAE J1349:2011)

496 HP

Net Power (ISO 9249:2007)

502 HP

Overview

Do More with Less

The Cat® 836 Landfill Compactor is designed with heavy-duty main structures that support multiple life cycles. It features a Cat C18 engine, single-lever steering, pressurized cab, and wheel/tip options that provide extended service life. Available Cat Compact Technologies, such as Compaction Control, further enhance compaction performance and consistency by providing accurate compaction values and 3D mapping.

Benefits

IMPROVED PERFORMANCE

Improved operation with smoother directional shifts due to Cat locker differentials<br /><br /><br />

ENHANCED TECHNOLOGY

Boost your productivity with standard technologies like Cat Compact with Pass Mapping and optional Cat Compact with Elevation Mapping<br />

IMPROVED GUARDING

New features such additional axle Duo-cone® seal guards, eyebrow guards, and new reversing fan guard protect the machine from trash intake and<br />other onsite hazards

Features at a Glance

- OPERATOR COMFORT AND CONTROL

-

- Flip-up armrest for easy ingress/egress.

- Keep your operators informed about machine conditions and operation with Vital Information Management System (VIMS™) 3G machine monitoring system.

- Enhanced visibility with standard rearview camera.

- Preferred temperature settings maintained with automatic climate control.

- Cat Premium Plus seat with standard features including leather finish, forced air heating and cooling, two-way thigh adjustment, power lumbar and back bolster adjustment, and dynamic end dampening to provide total comfort throughout the workday.

- Increased forward visibility with lowered glass for better visibility to the blade and wheels.

- BECAUSE UPTIME COUNTS

-

- Easy access and in a controlled environment; electronics bay is located inside the cab.

- Focused on safety with ground level or platform access to most major components.

- Ground level: emergency shutdown, battery disconnect, and jump start.

- Quick visual inspection and minimize fluid contamination with sight gauges for coolant, transmission, and hydraulic oil.

- Electronic air inlet restriction indicator.

- Designed for ease of service and inspection

– Hydraulic oil cooler, fuel cooler, and roof-mounted condenser

– Centralized grease points - Operators and technicians can resolve any problems before failure using VIMS.

- Underhood lighting for improved visibility of service points.

- Improved guarding around the axles mitigates risk of damaged components.

- Improved radiator air inlet door sealing to reduce radiator cleanout.

- Remaining useful life of the engine air filter allows for better planning of maintenance and repair activities.

- POWERFUL EFFICIENCY

-

- Improved performance, long life, low emissions.

- High productivity and fuel efficient.

- Two engine options available that meet U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 emission standards or Brazil MAR-1 and China Nonroad Stage III emission standards, U.S. EPA Tier 3 and EU Stage IIIA equivalent.

- For the Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 option, the Cat Clean Emissions Module contains a diesel oxidation catalyst, diesel particulate filter, and Cat Regeneration System, utilizing selective catalytic reduction (SCR) technology.

- Regeneration is completely automatic and does not interrupt the machine’s work cycle.

- Experience maximum responsiveness and control with Steering and Transmission Integrated Control System (STIC™).

- Conserve more fuel with the automatic engine and electrical system shutdown.

- Achieve greater momentum on grades and fuel savings by carrying that momentum through the shift points advanced productivity electronic control system (APECS) transmission controls.

- Operators experience less fatigue with throttle lock to maintain engine speed.

- Equipped with Cat torque converter with lock-up clutch which eliminates torque converter (TC) losses while lowering system heat and transfers more power to the ground.

- Improved direction shift speed with new Cat locker differentials.

- Diesel exhaust fluid (DEF) injector phase change tank to reduce engine idle time at shutdown.

- Increase machine tarp lift capability to eliminate need for track type tractor to carry tarp rolling equipment for end of day landfill cover.

- PRODUCTIVITY WITH TECHNOLOGY

-

- Compact technology combines advanced compaction measurement, in-cab guidance, and reporting capabilities to help you consistently meet compaction targets fast, uniformly, and in fewer passes – saving on fuel and the cost of unnecessary rework.

- Link technology (standard) provides access to machine location, hours, fuel consumption, idle time, events, and diagnostic codes through the online VisionLink® interface.

- Improved productivity with standard Cat Compact with Pass Mapping and 10" display.

- Slope indicate feature improves construction of slopes and identifies when risk for fluid cavitation occurs.

- Improved productivity with optional Cat Compact with Elevation Mapping.

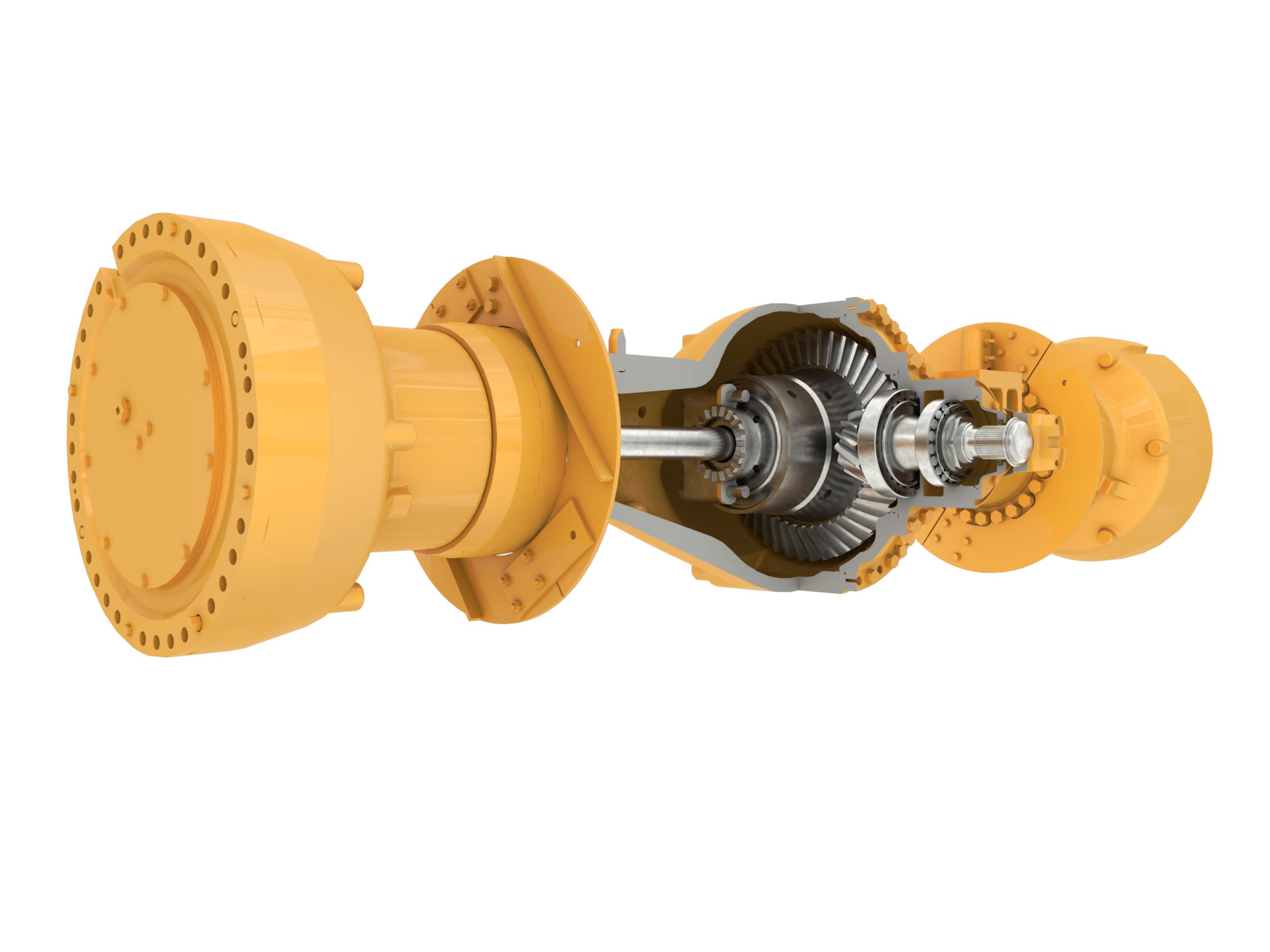

- LONG TERM VALUE AND DURABILITY

-

- Larger diameter axle shafts, the Cat locker differentials, improved duo cone labyrinth, thicker wheel at the spindle for increased strength.

- Improved final drive gear set to reduce stress and enhance pitting life.

- Fan motor guard to prevent bag wrapping.

- 5" higher efficiency fuel filter for cleaner fuel to the engine.

- WHEEL TIPS BUILT TO PERFORM

-

- Designed specifically to complement Cat machines.

- Improves machine performance through longer wear life and maintaining traction.

- Five wheel and tip configurations are available to meet your particular application:

1) Paddle Tip – High performance and less fuel burn with more traction and less weight.

2) Plus Tip – Traditional design for increased side slope stability.

3) Combination Tip – Both paddle and plus tips provide the best compromise of performance and fuel economy with side slope stability.

4) Diamond Tip – Longest life tip on the market with reputation of reliability that is world class in the waste tip industry.

5) Chopper Tip – These types of tips are recommended for wet/soft waste where chopping and/or traction is a large concern and abrasive wear life is not a major concern.

Specifications

Full Specifications

- Engine - Tier 4 Final/EU Stage V

-

Gross Power (SAE J1995:2014)

562 HPNet Power (SAE J1349:2011)

496 HPNet Power (ISO 9249:2007)

502 HPEngine Model

C18Emissions

U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V and Japan 2014Rated Speed

1900 r/minTorque Rise

52Bore

5.71 inStroke

7.2 inDisplacement

1104.5 in³High Idle Speed

2120 r/minLow Idle Speed

750 r/minMaximum Altitude without Derating

7500 ftNote

*Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator.

- Operating Specifications

-

Maximum Operating Weight (Tier 3/Stage IIIA equivalent)

125622 lb

- Transmission

-

Transmission Type

Planetary - Powershift - ECPCDirect Drive - Forward 1

4.3 mile/hDirect Drive - Forward 2

7.8 mile/hDirect Drive - Reverse 1

4.6 mile/hDirect Drive - Reverse 2

8.2 mile/h

- Hydraulic System - Steering

-

Steering System - Circuit

Flow Sharing Implement; Pilot, load sensingSteering System - Pump

Piston – Variable DisplacementRelief Valve Setting - Steering

3495 lb/in²Total Steering Angle

86Steering Cycle Times - High Idle

3.9 sSteering Cycle Times - Low Idle

6.4 s

- Service Refill Capacities

-

Fuel Tank

209.0 gal (US)Diesel Exhaust Fluid Tank*

9 gal (US)Cooling Systems - Tier 4 Final/EU Stage V

40 gal (US)Cooling System - Tier 3/Stage IIIA Equivalent

37.2 gal (US)Engine Crankcase

16 gal (US)Transmission

21.9 gal (US)Differential - Final Drives - Front

49.0 gal (US)Differential - Final Drives - Rear

50.0 gal (US)Hydraulic System - Implement/Steering

46.2 gal (US)Hydraulic Tank Only

27.2 gal (US)

- Axles

-

Front

Planetary – FixedRear

Planetary – OscillatingOscillation Angle

±6°

- Braking System

-

Service Brakes

Multi Disc Wet (Enclosed) 2 WHLParking Brake

Spring Applied, Hydraulic Released

- Sound Performance - Tier 4 Final/EU Stage V - Standard

-

Operator Sound Level (ISO 6396)

72 dB(A)Machine Sound Level (ISO 6395)

111 dB(A)

- Sound Performance - Tier 4 Final/EU Stage V - Suppression

-

Operator Sound Level (ISO 6396)

72 dB(A)Machine Sound Level (ISO 6395)

109 dB(A)

- Dimensions (Approximate)

-

Height to Top of Beacon

15.2 ftHeight to Top of Air Conditioning Condenser

15.2 ftHeight - Cab Roof

14.1 ftHeight - Top of Exhaust Pipe

15.1 ftHeight - Top of Hood

11.3 ftGround Clearance to Hitch

2.1 ftGround Clearance to Bottom of Bumper

3.2 ftCenterline of Rear Axle to Rear Compactor Guard

11.3 ftHitch to Centerline of Front Axle

7.5 ftWheel Base

14.9 ftWidth over Front Striker Bars

12.9 ftWidth over Rear Striker Bars

12.9 ftWidth over Platform

10.5 ftWidth over Drums

14.0 ft

- Straight Blade

-

Capacity

25.9 yd³Height

7.3 ftHeight of Cutting Edge

7.3 ft

- Semi U-Blade

-

Capacity

29.3 yd³Height

7.3 ft

- U-Blade

-

Capacity

33.6 yd³Height

7.4 ft

Equipment

- Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

POWER TRAIN

- Advanced Productivity Electronic Control Shifting (APECS)

- Air to air aftercooler

- Brakes, fully hydraulic, enclosed, wet multiple disc brakes

- Cat Clean Emission Module, insulated (Tier 4 Final/Stage V/Korea Stage V and Japan 2014)

- Electro hydraulic parking brake

- Engine, Cat C18: – Tier 4 Final/Stage V/Korea Stage V and Japan 2014 – Tier 3/Stage IIIA equivalent

- Fuel priming pump, electric

- Fuel to air cooler

- Ground level engine shutoff

- Guard (3 piece) transmission

- Heat shield, turbo and exhaust manifold

- Hydraulically driven demand fan

- Integrated braking

- Radiator, Aluminum Modular Radiator (AMR)

- Separated cooling system

- Starting aid (ether) automatic

- Throttle lock

- Torque converter with lockup clutch (LUC)

- Turbine precleaner, engine air intake

- Transmission, planetary, with 2F/2R speed range control

- Underhood ventilation system

ELECTRICAL

- Alarm, back-up

- Alternator, 150 amp

- Batteries, maintenance-free (4-1,000 CCA)

- Converter, 10-15 amp, 24V to 12V

- Lighting system, halogen (front and rear)

- Lighting, access stairway

- Starter, electric (heavy duty)

- Starter lockout (ground level)

- Starting receptacle for emergency start

- Transmission lockout (ground level)

OPERATOR ENVIRONMENT

- Air conditioner w/roof-mounted condenser

- Cab, sound-suppressed and pressurized

- Internal four-post rollover protective structure (ROPS/FOPS)

- Radio ready for (entertainment) includes antenna, speakers and converter (12V, 10-15 amp) 12V power port for mobile phone or laptop connection

- Camera, rear vision

- Coat and hard hat hooks

- Flip-up armrest

- Heater and defroster

- Horn, electric

- Hydraulic controls (floor mounted)

- Implement hydraulic lockout

- Laminated glass

- Light, (dome) cab

- Lunchbox and beverage holders

- Instrumentation, Gauges: – DEF fluid level (Tier 4 Final/Stage IV) – Hydraulic oil temperature – Speedometer/tachometer – Torque converter temperature

- Instrumentation, Warning Indicators: – Action alert system, three category – Axle/brake oil temp, front – Brake oil pressure – Electrical system, low voltage – Engine failure malfunction alert and action lamp

- Mirrors, rearview (externally mounted)

- Parking brake status

- Radio, CB (ready)

- Seat, Cat Comfort, (cloth) air suspension

- Seat belt, retractable, 76 mm (3") wide

- STIC Control System with steering lock

- Sun visor, front

- Glass (window) - rubber mounted glass

- Transmission gear (indicator)

- Vital Information Management System (VIMS) with graphical information display: external data port, customizable operator profiles

- Wet-arm wipers/washers (front and rear)

- Intermittent wipers (front and rear)

WHEELS

- Wheels, paddle, plus, combination, and diamond wheel configurations

GUARDS

- Guards, axle (front and rear)

- Guards, cab window

- Guards, crankcase and power train, hydraulically powered

- Guards, rear fan and grill

BLADES

- Bulldozer arrangement is included in the standard equipment. Bulldozer blades are optional.

FLUIDS

- Antifreeze, premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

OTHER STANDARD EQUIPMENT

- Auto Blade Positioner (ABP)

- Demand fan/swing out (hydraulic reversible)

- Doors, service access locking

- Ecology drains for engine, radiator, hydraulic tank

- Electronic clutch pressure control and remote mounted pressure taps

- Emergency platform egress

- Engine, crankcase, 500 hour interval with CJ-4 oil

- Fuel tank, 793 L (210 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic oil cooler

- Hydraulic, steering and brake filtration/screening system

- Oil sampling valves

- Product Link™ - Cellular

- Stairways, fixed-L/R (rear access)

- Steering, load sensing

- Vandalism protection caplocks

- Venturi stack

- Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

Various blades:

- Straight blade

- U-blade

- Semi U-blade

Various tip and wheel arrangements:

- Paddle

- Plus

- Diamond