Engine Rebuild Center: Experience the Foley Difference

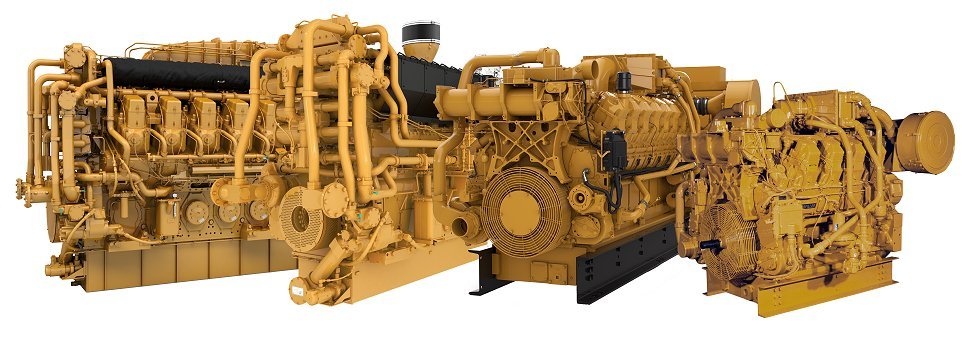

Foley’s Engine Rebuild Center keeps Oil & Gas customers running strong. We rebuild 3616 engines and everything on down the line.

If you don't believe in excuses, you've come to the right place.

Many Cat engines are rebuilt for a second life at the Foley Engine Rebuild Center located centrally in Park City, Kansas. We specialize in Cat 3616 to 3304 engines, with our main area of focus being in the oil and gas industry.

The performance we promise is the performance you get. No bull. If we can't meet your schedule, we tell you upfront before the work begins. Straight up answers with quoted upfront costs.

Get Your Quoted Cost Upfront, No Add-On Charges or Overages

One of the things that has made Foley the first choice for engine rebuilds is that we provide customers with a flat rate that is devoid of any overages and add-ons. Machine shop work, additional parts and labor are all included upfront on engines that are operational.

It’s not uncommon for engine rebuild costs in the oil and gas industry to be 20%+ higher than the initial quote due to incomplete scope of work, unforeseen problems or additional repair time.

This is something you won’t experience when you partner with Foley.

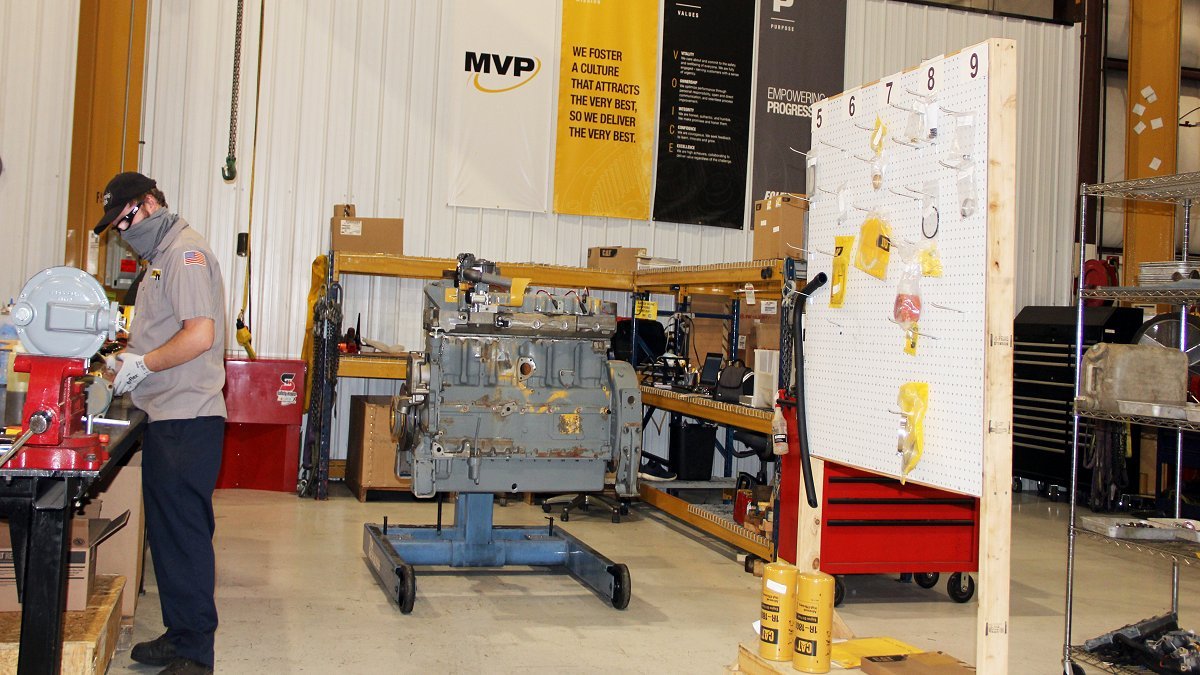

Technicians that Know the Oil & Gas Industry, Not Just Engines

When you choose to work with Foley’s Engine Rebuild Center, you get more than best-in-class trained technicians. You get a hardworking team of Kansans that understand oil and gas.

While 90% of Kansas is dedicated to agricultural production, we also have more local oil and gas operators than any other region in the United States. We know oil and gas. We understand this industry’s importance to providing energy and security to our nation and the world. Our team knows what it means when your system is down and will work diligently to get it up and running again in the shortest amount of time possible.

Expect Clear Communications, Timely Answers and Realistic Expectations

Our technicians have decades of experience and know exactly what it takes to re-build a quality engine within a tight deadline.

Each rebuild that goes through our Engine Rebuild Center has one point of contact throughout the entire rebuild process. Your designated contact will take your engine and you – through the entire rebuild process every step of the way.

Get An Inside Look at the Foley Engine Rebuild Center with Jon Robinson

When you choose Foley Equipment’s Engine Rebuild Center, you get more than best-in-class trained technicians. You get a team that understands what it means when your machine is down and who will work diligently to get the engine rebuilt and running again.

You get a plan with clear communications, timely answers and realistic expectations delivered.

Conveniently Located in the Heart of America

Our Foley Engine Rebuild Center is dedicated to high quality and high volume rebuilds of Cat 3616 to 3304 series engines with some of the tightest production deadlines around.

Because of our heartland location, most engines can get to our location overnight and be in the shop the next day for an early morning evaluation followed with a recommended repair solution and rigorous timeline for completion.

Experience the Foley Difference for Yourself

With our unmatched warranties and after sales support, we invite you to experience the Foley difference for yourself. We understand that your work can’t wait, so neither can you. Don’t just invest in power, invest in a powerful solution backed with a heritage built on dependability.

Foley's Engine Rebuild 9-Step Process

Here is how we deliver like-new performance for a fraction of the cost.

1) INSPECTION/EVALUATION

This vital first step is a thorough process during which we develop a customized rebuild plan and cost estimate for you. The specific needs of your engine are determined through a comprehensive evaluation.

2) DISASSEMBLY

This vital first step is a thorough process during which we develop a customized rebuild plan and cost estimate for you. The specific needs of your engine are determined through a comprehensive evaluation.

3) RECONDITIONING

This phase of the process addresses equipment needs not typically included in an engine overhaul.

4) ENGINEERING UPDATES

During reassembly, your engine will receive any required updates and your choice of optional performance enhancement upgrades that have occurred since your engine was originally manufactured.

5) REASSEMBLY

Our professional technicians will carefully and completely reassemble your engine.

6) TESTING & VALIDATION

Following the original commissioning procedures of the rebuild process, the engine will be retested and re-commissioned.

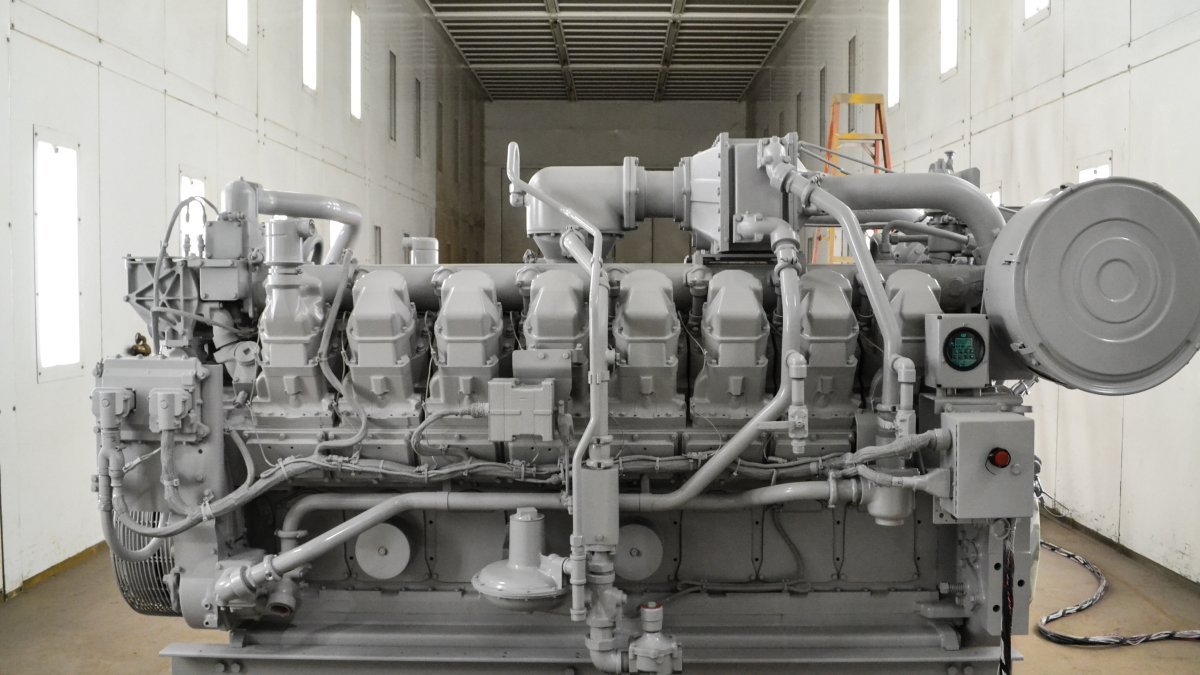

7) REPAINTING

Your engine will perform like new and look like new—after a paint job. A Cat Certified Engine Rebuild decal also will be issued.

8) NEW CAT CERTIFIED ENGINE REBUILD IDENTIFICATION NUMBERS

A new Cat Certified Engine Rebuild number identifies your engine and entitles you to Caterpillar extended service coverage options.

9) CUSTOMER EVALUATION

The rebuild process is not considered complete until your operators are satisfied with the performance of your engine in its working environment.