H190 S Hydraulic Hammer

Performance Hammers

Virtual Product Tour

Details

Impact Energy Class

13000 ft·lbf

Blows per Minute

370 -530

Minimum Operating Pressure

2,175 psi

Overview

The H190 S hammer is a valuable asset in quarries and bridge demolition, as well as the largest-scale demolition projects.

Features at a Glance

- Increase Production

-

- Hammer hits with consistent power, delivering constant production.

- Operation cycle is more efficient - less waste in internal heat, more power delivered to the tool.

- Piston and tool are matched in diameter and mass, greatly increasing efficiency in power transmission.

- Blow frequency, hydraulic pressure and impact energy have been tuned to produce the highest possible work rates on Cat machines.

- Lower Maintance Costs

-

- No need for constant checking of the gas charge. Design keeps gas pressure steady through the duration of the annual service interval.

- All daily checks and routine service can be performed with the hammer attached to the machine.

- Spend more time working and less time on service. Greasing can be performed quickly from one standing-height grease point.

- Service the lower bushing in the field using simple hand tools.

- Lower bushing is rotatable – more service life lower parts cost.

- Available for extreme environments, the optional wear package protects the hammer housing from damage.

- Focus on Your Business, Not Your Hammer

-

You don't need to be a hammer expert as our expertise is on call for you. Built-in features like automatic shut-off protect your equipment from poor operation techniques or the occasional mistake. Internal buffering and integral silencing keeps the noise and power on the job, and out of the cab. If you can run an excavator, you can run a Cat hammer like a pro.

- Easy to Operate

-

- Auto shut off prevents blank firing, the leading cause of user-induced damage to hammers

- On a Next Gen Cat Excavator, hammers are protected by Auto-Stop, preventing damage from over-hammering in a single spot.

- This feature helps prevent damage to your machine and premature damage to your hammer, even with inexperienced operators

- Performance Hammers lead in both operator comfort and machine protection.

- The buffering system qualitatively dampens vibration to the machine due to proprietary buffering material.

- Can be configured for joystick or foot pedal control to suit your operating preference.

- Spend Less Time on Maintenance

-

- Rotate or change the bushing in less than an hour.

- Gas checks are annual, and quickly accomplished without dismounting the hammer.

- You can do this yourself… or your Cat dealer can provide comprehensive support on your schedule.

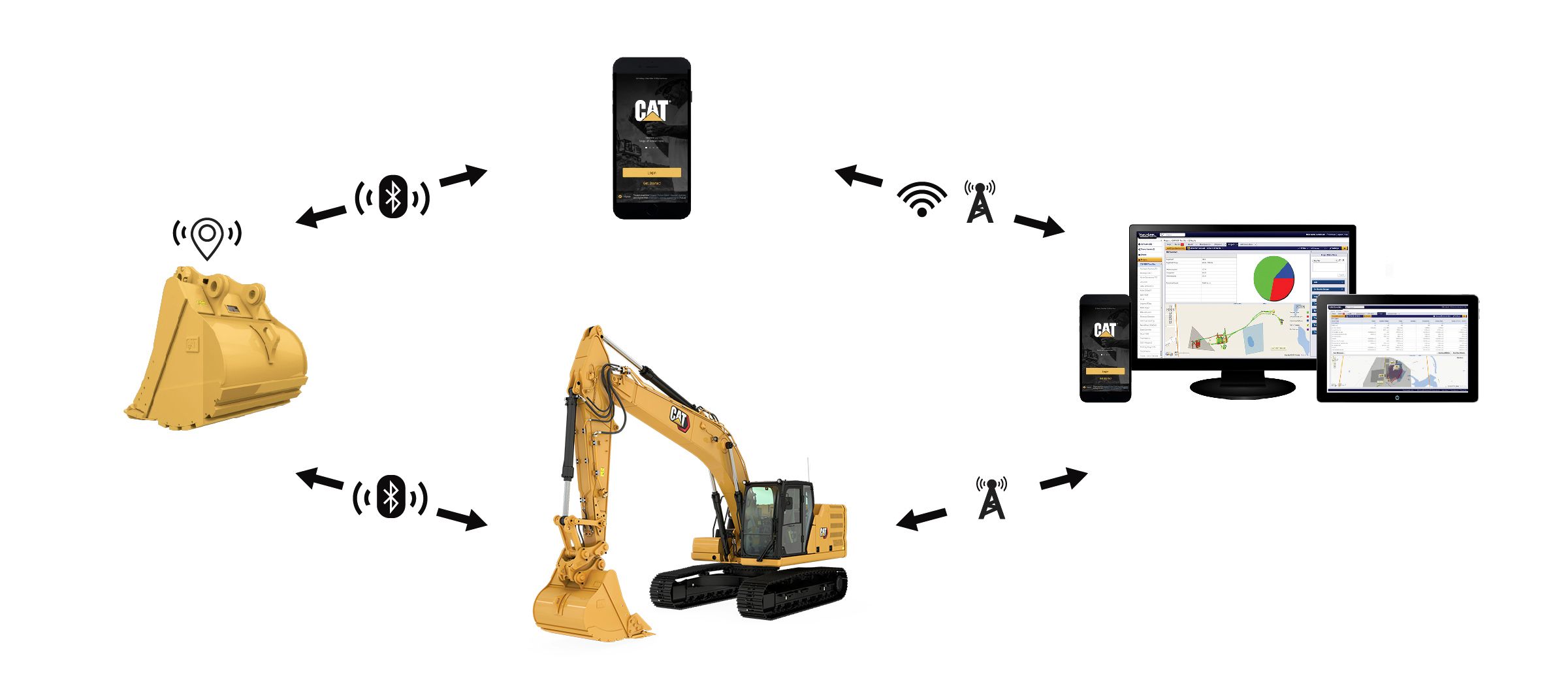

- Next Level Technology

-

- All models include Product Link technology standard, you can locate the hammer via the Cat App on your phone.

- When paired with a Next Gen Cat excavator, the hammer is automatically recognized and configured

- Cat hammer dimensions are included in Cat E-Fence technology – protects the cab, and keeps the hammer in safe areas on the job site.

- Hammer pressure and flow controls can be monitored and configured via the in-cab monitor – manually or automatically.

- Auto-Lube is Standard

-

The H190 S Hammer inclues a hammer-mounted autolube. Every time the hammer is activated, it's automatically greased, keeping it at peak performance for the entire shift.

- Beyond Your Purchase

-

Want to learn more about your hammer? Operating and maintenance videos are available online or through your local Cat dealer. Working away from home? Not a problem. Be confident no matter where your job takes you as the global network of Cat dealer is there with not only equipment support and service, but also with the hammer parts and service you may need as well. No other manufacturer can offer you the same.

Specifications

Full Specifications

- Details

-

Impact Energy Class

13000 ft·lbfBlows per Minute

370 -530Minimum Operating Pressure

2,175 psiMaximum Operating Pressure

2,320 psiMinimum Carrier Weight

94,798 lbMaximum Carrier Weight

176,368 lbMinimum Rated Flow

74 gal/minMaximum Rated Flow

101 gal/minTool Shaft Diameter

7.5 inMinimum Operating Weight

11440 lbMaximum Operating Weight

12430 lb