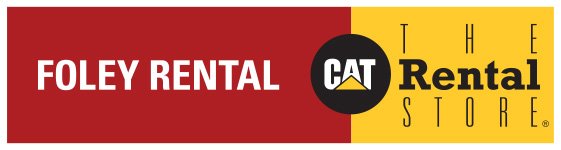

MB200 Mixing Bucket

Mixing Buckets

360° View

Details

Capacity

0.26 yd³

Width

54.6 in

Required Hydraulics

Standard Flow

Overview

Utilizing a paddle auger and hydraulically controlled chute door to mixing material in a variety of applications.

Features at a Glance

- Easy Material Addition

-

Cement bag breakers on top of mixing bucket grate allow for easy breaking and addition of bagged materials.

- Bucket Cutting Edge

-

Cutting edge allows for bucket to be used to drive into piles of raw materials.

- Reinforced Steel Bucket Cavity

-

Reinforced steel is used for bucket cavity ensuring long life and reduced wear.

- Bolt-On Replaceable Auger Paddles

-

Replaceable, bolt-on auger paddles are hardened and reach throughout the bucket to combine all material.

- Remotely Operated Chute Door

-

Hydraulically controlled chute door allows material to be dispensed all from the cab of the host machine.

- Bolt-On Serrated Step

-

Serrated step allows safe and ergonomic access to machine cab that is easily replaceable if damaged.

- Tool Mounted Operation and Maintenance Manual Holder

-

Tool mounted and sealed from the elements, this holder includes all of the operation manuals and mantenance guides required for proper operation of the work tool.

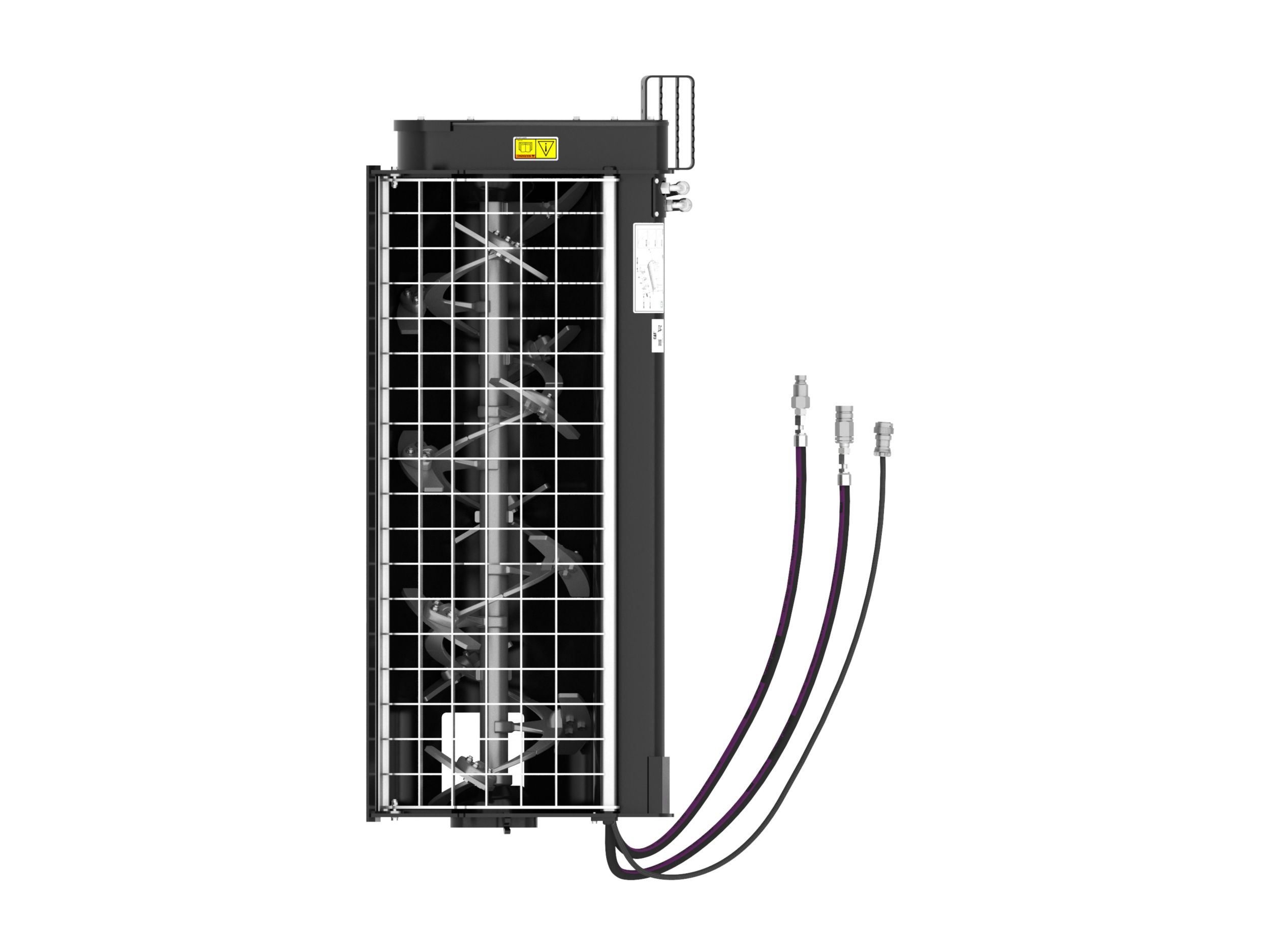

Specifications

Full Specifications

- Details

-

Capacity

0.26 yd³Width

54.6 inRequired Hydraulics

Standard FlowAuger Speed Range

10-30 rpmDrive Method

ChainHeight

28.8 inLength

27.3 inOptimal Hydraulic Flow

60-70 lpm (16-18 gpm)Optimal Hydraulic Pressure

140-200 bar (2031-2901 psi)Weight

639 lbAuger Diameter

16 inNumber of Auger Paddles

12Interface Type

Skid Steer CouplerOverall Width

63.1 in