HogZilla Monster Grinders: Not Your Run-Of-The-Mill Product

That inexpensive bag of mulch you buy for your lawn or garden is likely the product of a highly specialized, million-dollar piece of equipment — like the industrial grinders produced by CW Mill Equipment Company. CW Mill Equipment Company, a family-owned company counts mulch producers among its top-three Customers, along with municipalities and land-clearing contractors who need to remove trees, stumps, logs and other types of wood waste.

CLIENT: CW Mill Equipment Company

LOCATION: Sabetha, Kansas

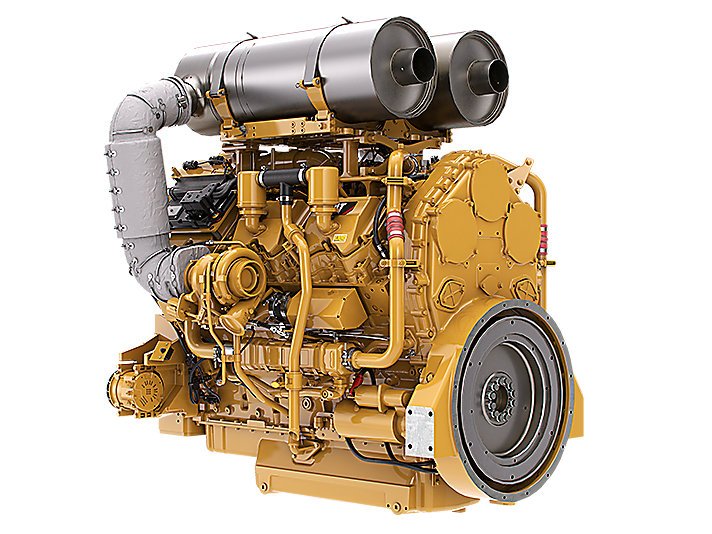

PRODUCT USED: Cat C32 Industrial Engine, U.S. EPA Tier 4 Final & E.U., Stage IV compliant

Introduction

Founded in 1973, CW Mill manufactures a full line of diesel- and electric-powered tub and horizontal grinders under the HogZilla Monster Grinders brand.

The company’s popular TC Series features a torque converter that drives a hammermill assembly to multiply engine torque for maximum production. On the TCII Series, that hammermill assembly adjusts to match different mill diameters and depths of cut in the field — increasing versatility and resale value.

Today, all diesel HogZilla grinders are powered by Cat industrial engines, but that wasn’t always the case.

“For the first 10 years or so, we used another brand. A light bulb went off when a Customer told me, ‘You can sell that grinder four out of 10 times, but if it had a Cat engine, you could sell it 10 out of 10 times,’” says Tim Wenger, vice president, owner and sales manager at CW Mill.

A HANDS-OFF SOLUTION

When the time came to equip its grinders with Tier 4 Final engines, CW Mill was apprehensive. Customers relayed stories about truck engines that were constantly in the shop for repairs. The regeneration process used in certain engines created extra heat, raising concerns about fire hazards around wood fiber.

Wenger sat down with Foley Equipment and Caterpillar to learn about plans for the Cat C32 U.S. EPA Tier 4 Final industrial engine and was ecstatic to discover it used only dual-can diesel oxidation catalysts (DOC) to reduce emissions. “I wanted to jump across the table and hug them,” he says.

KEEPING IT SIMPLE

C32 Tier 4 Final models don’t require Diesel Exhaust Fluid (DEF) and use normal heat from the engine exhaust for transparent regeneration which occurs automatically without operator intervention. That simplicity appealed to CW Mill, which has learned over the years that industrial grinder Customers don’t appreciate complication. “We try to keep it simple, keep it reliable, keep it productive and that keeps it profitable for the Customer. Cat engines help us do that,” Wenger says.

POWERING IT UP

As it moved from Tier 2 to Tier 4 Final, CW Mill upgraded from the C27 (D rating duty cycle) to the C32 at 1,000 horsepower (B rating). The switch allows Customers to run the engine at maximum power 60-70% of the time, in line with real-world grinder use.

The company also chose to use a Cat cooling package instead of supplying its own, simplifying application and installation auditing as well as future warranty claims. “With no aftermarket radiator, piping, fans or dryers to worry about, CW Mill knows their Customers are covered by the Cat warranty,” says Ed Beatty, OEM accounts manager for Foley Equipment.

PROMISING PEACE OF MIND

Strong dealer and warranty support is a must for CW Mill, which despite its small size prides itself on offering high levels of service after the sale. The company supplements the standard Cat engine warranty with Platinum Extended Service Coverage from Foley to give Customers maximum peace of mind.

Extended Service Coverage (ESC) provides protection against unexpected repair bills and rising parts and labor costs. It covers 100% of the cost of parts and labor on not just the covered parts that fail, but also any resultant damage to other Cat parts. And because all ESC options are 100% transferable at no additional cost, it may increase the resale value of your engine.

“The engine is the biggest expense on a grinder, and most Customers can’t work on it themselves. This way, they can call their Cat dealer with little or no out-of-pocket cost on their end,” Wenger says.